R, E Series – Vertical Laminar Flow Work Stations

|

Applications: Semiconductor Manufacturing, Non-Toxic Manufacturing, Curing, Thin Film Manufacturing, Optical Assembly

R SERIES Recirculating: A free-standing console design providing an ISO 5 / Class 100 atmosphere in an operator workstation environment. Completely self-contained, it functions efficiently in an uncontrolled area. Air passes through a HEPA filter (99.99% efficient on .3 microns) & flows continuously downward in the work chamber & through perforated stainless steel work surface. The majority of the air is re-circulated back through the filter, the balance flows out of the front chamber to be replaced by fresh air. Provides control against cross-contamination within the chamber. The unit is stationary, allowing permanent electric, gas and water services individually tested and certified to meet the specifications for Laminar Flow Clean-Air Devices as per Institute of Environmental Science IES-RP-CC-002-89. E SERIES: Exhausting: Designed as an exhausting vertical laminar flow workstation, it is to be used when toxic odors & fumes are present. Intake air passes through a HEPA filter (99.99% efficient on .3 microns) providing an ISO-5 / Class 100 airflow into the work chamber & downward through the perforated work surface. It is then exhausted through rear plenum wall & exhausted at the top of the unit. A remote exhaust air system is required to balance the work chamber’s airflow pattern. Storage space is available underneath the work surface. Units are individually tested & certified to meet or exceed the specifications for Laminar Flow Clean-Air Devices as per Institute of Environmental Science IES-RP-CC-002-86 Filter: Three inch HEPA (High Efficiency Particulate Air) type, aerosol challenged, zero probed. Aluminum frame mini-pleat design, Minimum efficiency of 99.99% at .3 microns. Prefilter: 1″ bonded polyfiber media minimizes surface-loading. Quick-release aluminum frame. Easily accessible from front of unit. 78 % arrestance – 56-57 ASHRAE. Airflow: Average measured clean air velocity 80 fpm (+/-20 fmp), measured values within +/- 20% uniformity. Construction: Woodboard construction for minimum noise & vibration. White & blue plastic laminate finish. Front loading HEPA filters. Perforated stainless work surface; 1/4″ on 3/8″ staggered center. Supports ribs under work surface. Hinged acrylic face shield. Protective plastic egg crate diffuser screen in front of HEPA filter main uniform air velocity within the work area. Size of exhaust opening (at top of unit): V-324-E: 5″ x 36″; V-524-E: 5″ x 48″; V-624-E: 5″ x 60″; V-824-E: 2 each @ 5″ x 36″ Electrical & Power Requirements: All electrical components are UL / NEC Compliant. Standard 115V, 15 Amp, 1 pH, 60 Hz. SJO power cord w/ 3-prong ground plug. Motor/Blower Assembly: High efficiency motors to reduce electrical load. Motors are thermally protected & self-lubricating. High capacity metal forward curved blowers with direct drive motors. Lighting: Recessed 2 pin fluorescent lighting. 125 ft. Candle +/- 20 ft. Candles. Plastic prismatic lens cover maximizes light diffusion. Controls: Solid state, adjustable airflow control, 80-120 fpm, 15A max. load capacity, Internally mounted to prohibit accidental change. Illuminated switches on face panel for motor & lights. Options:

|

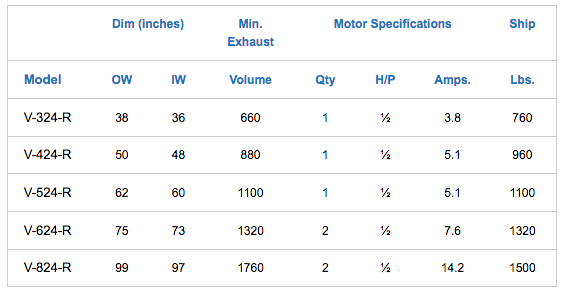

R SERIES Model/Dimensions:

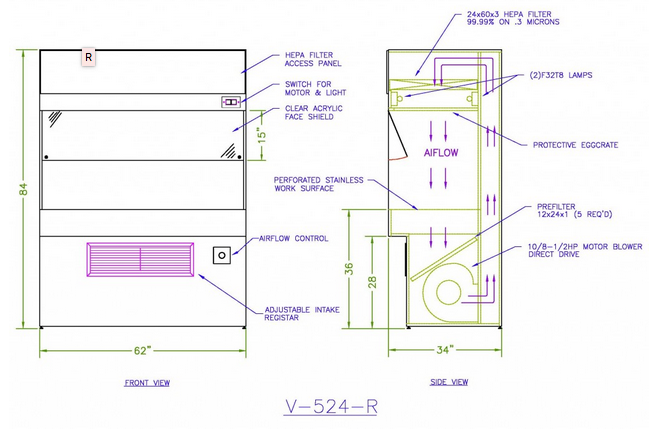

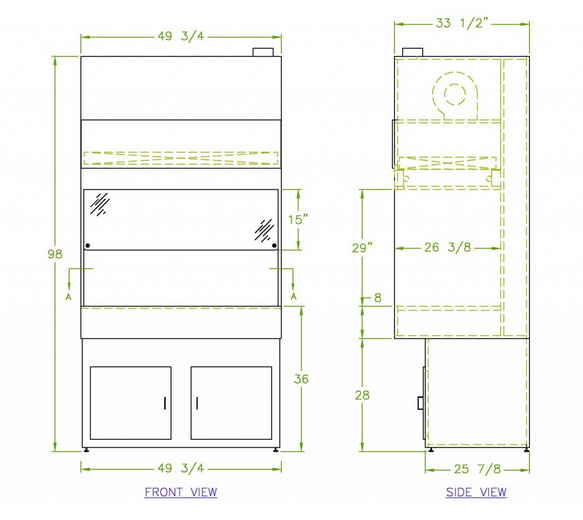

R SERIES Sample Drawings:

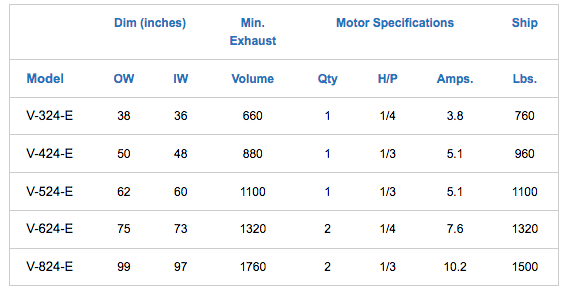

E SERIES Model/Dimensions:

E SERIES Sample Drawings:

Services |