Cleanroom, Hardwall & Softwall

PDE SERIES – Softwall Cleanroom Portable Downflow Clean Air Enclosure

|

Applications: Microelectronic Fabrication, Medical Device Manufacturing, QC Inspection, Sterile Filling & Packaging, Pharmaceutical Processing, Semiconductor Manufacturing

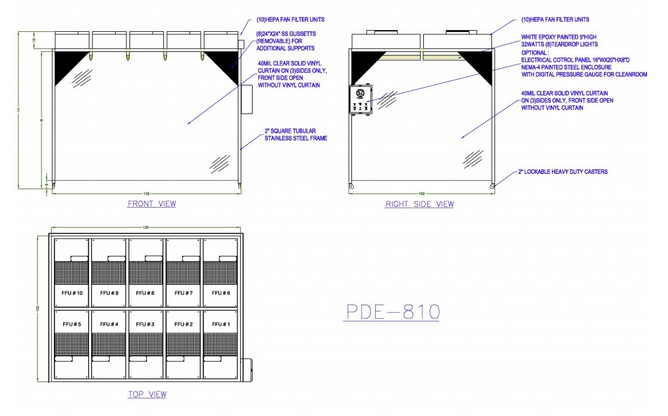

Description: The Fan Filter Unit draws ambient air from above & generates a uni-directional vertical airflow pattern that exits beneath the vinyl curtain. Depending on the quantity of modules used and filter efficiency an ISO 8 Class 100,000 to ISO 5 / Class 100 clean random airflow can be established inside the Softwall environment. The PDE Series includes: HEPA fan modules, cleanroom tiles, cleanroom light fixtures that provide 125 ft. candle coverage. The standard unit consists of tubular steel with a painted (or Stainless steel) finish, on lockable casters for mobility. A solid clear vinyl curtain spaced above the floor allows a continuous downflow purge of clean air. Pre-designed for product isolation and spot coverage over process equipment. Units can be linked together to provide multiple configurations. Construction: 2” or 3” square (tubular – 11 gauge) welded frame – Painted or Stainless Steel with heavy-duty lockable casters; Standard Inside ceiling is 8 ft. (others are available). Aluminum, gasketed, T-Grid ceiling system with 3/4” angle on perimeter. Pre-assembled at factory for easy installation. Gasketing ensures seal when installed. Solid, clear 40 mil vinyl curtain perimeter with overlapping entrance (or optional Polycarbonate walls). Electrical & Power Requirements: All electrical components are UL Approved / NEC compliant. Standard 115V, 15A 1 Ph, 60 Hz., 15 ft. SJO power cord with 3-prong ground plug. 230V also available. Motor/Blower Assembly: High efficiency Impellor motors reduce electrical load. Motors are thermally protected & self-lubricating. High capacity metal backward curved impellers within direct drive external rotor motors to reduce wear. Statically balanced to maintain constant airflow Lighting: Recessed 2 pin fluorescent “cleanroom” type sealed 4 bulb lights – 125 ft. candle +/-20 ft. candles. Plastic prismatic lens cover maximizes light diffusion. Controls: Solid state airflow control, 70-120 fpm. 15A load capacity. Individual switches for motor & lights. Drawings: A complete set will be provided for all Cleanroom projects with an easy installation guide included OR take advantage of LM Air’s – Six Step Cleanroom Solution – design assistance, project management, installation (LM Air’s trained staff) and maintenance. Options:

|

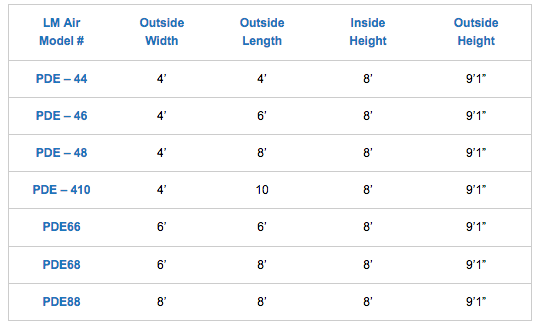

Model/Dimensions:

Sample Drawings:

Services |