PVE Series: Polypropylene Vertical Laminar Flow Workstation

|

Applications: Trace Metal and Research Labs,Semiconductor, Microelectronics, Waste & Water Treatment, Chemical Analysis, Pharmaceutical Manufacturing, Curing, Etching Processes, Plating Processes, Cleaning Processes, Photonics. Description: PVE Series offer Product protection within the work chamber - filtered air (ISO 14644) AND Operator protection by exhausting to the buildings exhaust system (tested to ASHRAE110) .Designed as an exhausting vertical laminar airflow clean workstation, it is to be used when toxic odors & fumes are present. Intake air passes through a HEPA or ULPA filter (99.99% efficient on .3 microns) providing an ISO 5 / Class 100 or better - airflow into the work chamber & downward through the perforated work surface. Air is then exhausted through the internal rear wall & ducted for discharge at the top of the unit. A remote exhaust air system is required to balance the work chamber’s airflow pattern. The use of polypropylene offers immunity to corrosion, resistance to acids & solvents, non-conductive properties, with minimal maintenance. Unit includes a vented, full depth base cabinet. Individually tested & certified to meet (exceed) the specifications for Laminar Flow Clean Air devices as per Institute of Environmental Science- IES-RP-CC-002-86, SEFA 8P; designed to meet national safety standards - NSF /ANSI 49 - the safety of products and personnel in the lab. Construction:

Airflow: Requires facility exhaust. Average clean air velocity 80 fpm (+/-20 uniformity). Negative resistance, .50 IWG Filter: HEPA (High Efficiency Particulate Air) or ULPA type, aerosol challenged, zero probed. Aluminum or Wood frame mini-pleat design. Minimum efficiency of 99.99% at .3 microns. (ULPA filters available) Prefilter: 1″ bonded polyfiber media minimizes surface-loading. 78% arrestance - 56-57 ASHRAE Electrical & Power Requirements: All electrical components are UL / NEC Approved. Standard 115V, 15A 1 Ph, 60 Hz. Motor/Blower Assembly: High efficiency motors to reduce electrical load. Motors are thermally protected & self-lubricating. High capacity curved blowers with direct drive motors or backward curved Impellors. LED Lighting: Recessed, sealed in Lexan -LED lighting. 125 ft. candle =/-20 ft. candles. Controls: Solid state, adjustable airflow control, 80-120 fpm, 15A max. load capacity, internally mounted to prohibit accidental change. Compact switches on face panel for motor & lights. Options:

|

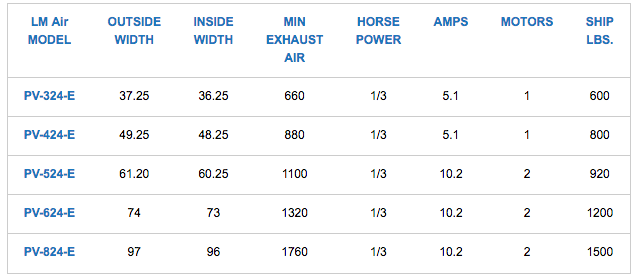

Model & Dimensions:

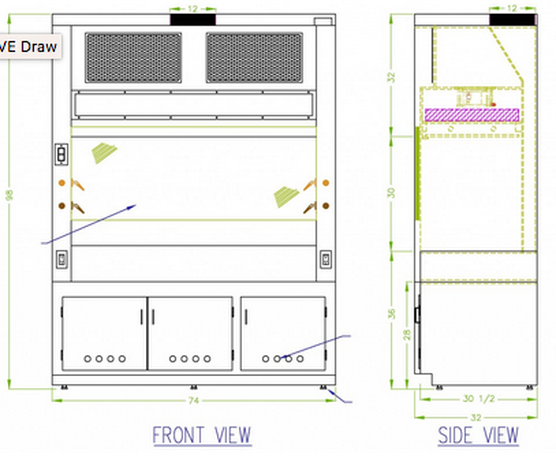

Sample Drawing:

Services |