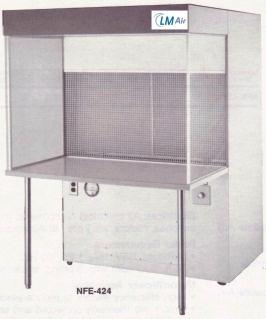

NFE Series – Negative Flow Exhausting HEPA Filtered Workstation

|

Applications: Microelectronic Manufacturing, Disc-drive Manufacturing, Hybrid Manufacturing, Pharmacology, Laser R&D, Optics, Thin Films, Foils & Plastics, Precision Engineering, Research Labs, Powder Filling and Handling, Critical Sample Preparation for Semiconductor, Cosmetics, Pharmaceutical & Aerospace industries

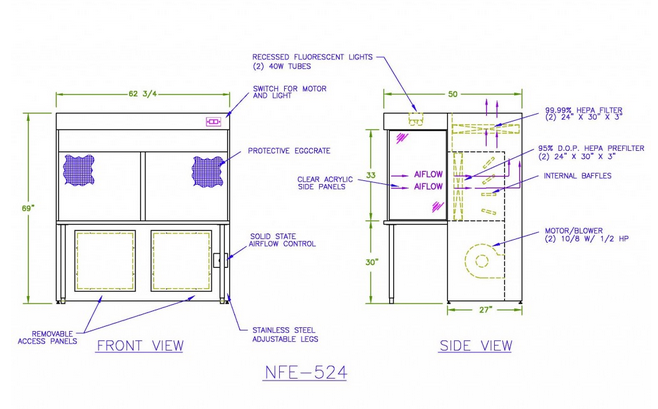

Description: Free-standing console provides containment of contaminated air through intake at work chamber. The initial pre-filter collects gross contaminants – the air passes thru an exhaust HEPA filter (High Efficiency Particulate Air, 99.99% efficient on .3 microns) for removal of the remaining contaminants to .3 microns. Use of exhaust filtration eliminates the need to duct to the outside. Units are individually tested for intake & exhaust velocities, per manufacturer’s specifications. The exhaust HEPA filter is tested & certified to meet or exceed the specifications for HEPA / ULPA filtration installation leak test of Institute of Environmental Science IES-RP-CC-002-86 [NOT TO BE USED FOR TOXIC FUME OR WITH ANY COMBUSTIBLE GAS] Filter-Exhaust: Three inch HEPA (High Efficiency Particulate Air) type, aerosol challenged, zero probed. Aluminum frame mini-pleat design. Minimum efficiency of 99.99% at .3 microns. Prefilter-Intake: Three inch HEPA (High Efficiency Particulate Air) type, aerosol challenged, zero probed. Aluminum frame mini-pleat design. Minimum efficiency of 95% at .3 microns. Airflow: Average measured clean air velocity 120 fpm. Construction: Woodboard construction for minimum noise & vibration. White & blue plastic laminate finish; laminated work surface & canopy. Clear acrylic side panes for visibility. Front loaded intake HEPA pre-filter; top loaded exhaust HEPA filter. Protective plastic egg crate diffuser screen in front of intake HEPA pre-filter & on top of exhaust HEPA filter. Electrical & Power Requirements: All electrical components are UL Approved. Standard 115V, 15A 1 Ph, 60Hz. 5ft. SJO power cord with 3-prong ground plug. NEC Electrical Code Motor/Blower Assembly: High efficiency motors to reduce electrical load. Motors are thermally protected & self-lubricating. High capacity metal forward curved blowers with direct drive motors. Fans statically balanced to maintain required airflow rate up to the initial static pressure Lighting: Recessed 2 pin fluorescent lighting. 125 ft. candle +/- 20ft. candles. Plastic prismatic lens cover maximizes light diffusion Controls: Solid state adjustable airflow control, 70-180 fpm, 15A max. load capacity, externally mounted for adjustment to intake velocity. Individually illuminated switches on face panel for motor & lights. Options:

|

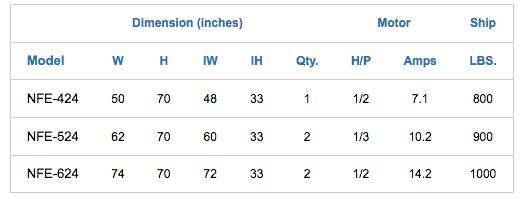

Model/Dimensions:

Sample Drawings:

Services |