Cleanroom, Hardwall & Softwall

TCS Series – Separate HEPA Filter & Blower Laminar Airflow T-Grid HEPA filtration Ceiling System

|

Applications: Microelectronic Fabrication, Medical Device Manufacturing, QC Inspection, Sterile Filling & Packaging, Pharmaceutical Processing, Semiconductor Manufacturing, Medical Operating Rooms

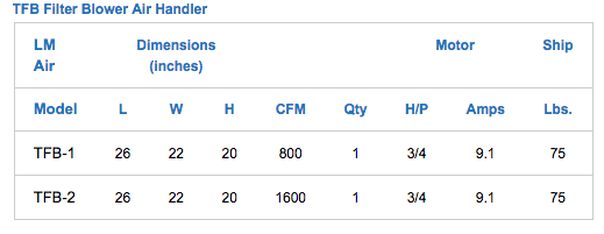

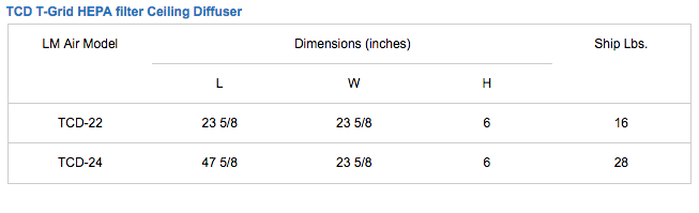

Description: The system’s flexibility provides protection of specific priority areas when a patterned ceiling coverage is specified. The system is designed to act as a HEPA filter source for Class 100 vertical laminar flow air when the building air system is not available. System components are: 1. TFB: Remote T-Grid blower air handler with flexible duct. 2. TCD: T-Grid HEPA filter ceiling diffuser. The blower unit can be suspended from the main ceiling or placed in a remote area. It can draw either ambient air from above the ceiling, or use inducted air supply. The duct connection size is1″dimt. Six feet of connection duct is provided per outlet. Blowers are designed in two versions: One outlet: drives one HEPA filter at 800 CFM Two outlets: drives two HEPA filter at 1600 CFM The filter diffuser mounts onto a standard 2′ x 4′ suspended T-Grid ceiling, and because of its shallow length (only 24″ is required for filter and duct connection), any low ceiling height can be converted into a cleanroom. The diffuser’s HEPA filter is enclosed in an aluminum housing. Space and weight saving separators are used to create the Mini-pleat microglass fiber filter media pack that is sealed to the housing with a urethane bonding agent. The diffuser has two ports for DOP testing and air balancing. TFB Motor/Blower:

TCD:

Prefilter: 1″ bonded polyfiber media positioned at intake of motor/blower Options:

|

Model/Dimensions:

Services |