DWS Series – Downflow Workstation – Vertical Laminar Flow Module on Frame

|

Applications: Microelectronic Manufacturing, Disc-drive Manufacturing, Semiconductor Processing, Hybrid Manufacturing, Pharmacology, Laser R&D, Optics, Thin Films, Foils & Plastics, Precision Engineering, Research Labs Description: Provides an ISO-5 / Class 100 (HEPA filters – 99.99% efficient on .3 microns) vertical laminar flow within the work chamber, protecting product being handled from outside contamination. The unit is stationary, allowing permanent electric, gas & water services. Wet chemistry process stations & isolated vibration-free tables under the module are easily interchangeable. Individually tested & certified to meet or exceed the specifications for Laminar Flow Clean-Air Devices as per Institute of Environmental Science IES-RP-CC-002-86. Filter: 3” HEPA (High Efficiency Particulate Air) type, aerosol challenged, zero probed. Aluminum frame minipleat design, minimum efficiency – 99.99% at .3 microns. Pre-filter: 1″ bonded polyfiber media minimizes surface-loading. Quick-release aluminum frame. Easily accessible from front of unit. 78 % arrestance – 56-57 ASHRAE. Airflow: Average measured clean air velocity 90 fpm (+/-10 fmp). All measured values within +/- 20% uniformity. Construction: Woodboard construction for minimum noise & vibration. White & blue plastic laminate finish. Protects plastic egg crate diffuser screen in front of HEPA filter maintain uniform air velocity within work area. Front ambient intake through louvered aluminum grilles. Front-loaded HEPA filters. Interior lining is Acrylic, Polypropylene or Stainless Steel located 30″ above floor at rear & side walls. 2″ sq. tubular Painted or Stainless Steel support frame (standard “H” design) w/levelers. Frame bolts together (with guides for head location). Electrical & Power Requirements: All electrical components are UL Approved. Standard 15 Amp, 1 pH, 60 Hz. SJO power cord w/ 3-prong ground plug. NEC Electrical Code Motor/Blower Assembly: High efficiency motors OR HEPA fan units to reduce electrical load. Motors are thermally protected & self-lubricating. Motors/Blowers are selected to maintain constant required airflow rate up to 2x the initial static pressure. Lighting: Recessed 1 pin fluorescent lighting. 125ft. candle +/- 20ft. candles. Controls: Solid state, adjustable airflow control, 80-120 fpm, 15A max. load capacity, internally mounted to prohibit accidental change. Illuminated switches on face panel for motor & lights. Options:

|

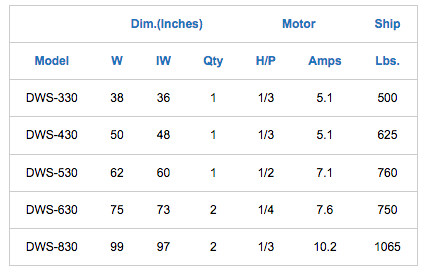

Model/Dimensions:

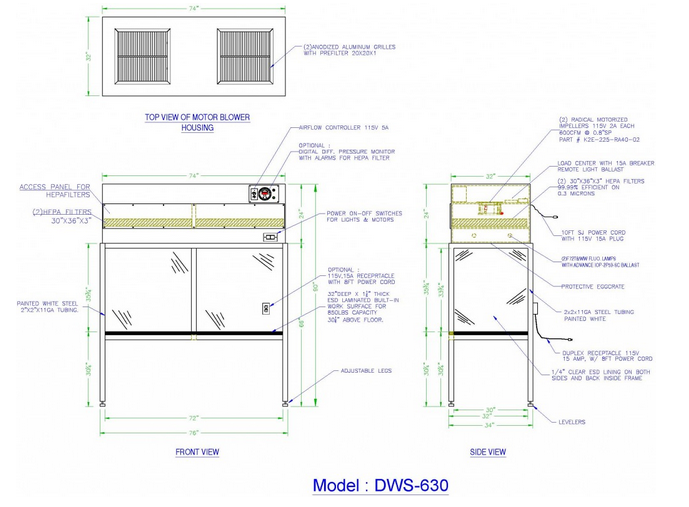

Sample Drawings:

Services |