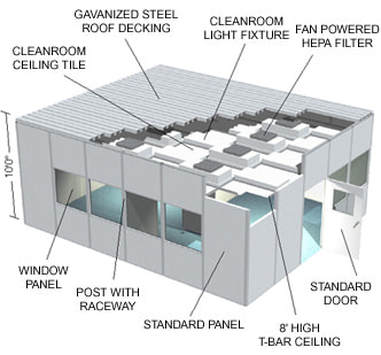

Cleanroom, Hardwall & Softwall

CRT Series

Cleanroom Tunnel Horizontal Flow with WM Series

|

Applications:

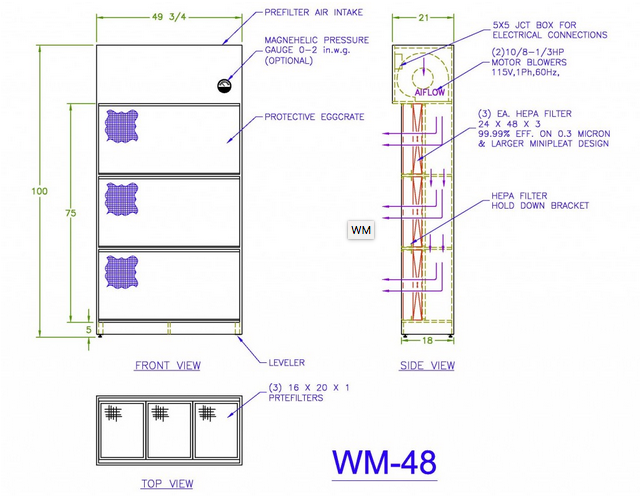

Microelectronic Fabrication, Medical Device Manufacturing, QC Inspection, Sterile Filling & Packaging, Pharmaceutical Processing, Semiconductor Manufacturing Description: Designed to create a clean zone with ISO-5 / Class 100 horizontal laminar airflow patterns, WM Series Horizontal airflow modules with HEPA (High Efficiency Particulate Air) filter, 99.99% efficient on .3 microns, are joined together in any width combination to form one wall, then connected to a prefabricated tubular steel frame. Tunnels are determined in size by the width and height of the HEPA filter horizontal laminar airflow wall modules combined with length of the tunnel enclosure. Ceilings & side walls are added by using clear acrylic panels and clear vinyl curtains. Air is totally displaced within the tunnel, from wall to wall & ceiling to floor. The airflow moves continuously throughout the tunnel, exiting from the open end & carrying with it airborne particulate matter. Airflow modules are individually tested and certified to meet or exceed the specifications for Laminar Flow Clean-air Devices as per Institute of Environmental Sciences IEC-RP-CC-002-86. Construction: 2” or 3” square (tubular – 11 gauge) welded frame – Painted or Stainless Steel with heavy-duty lockable casters; Standard Inside ceiling is 8 ft. (others are available). WM Series is located at the rear of the tunnel pushing cleanroom air from rear to the front. Woodboard construction for minimum noise & vibration. White plastic laminate finish. Front loaded HEPA filters with protective egg crate diffuser screen in front of the HEPA filter, maintaining uniform air velocity within work area. Pre-assembled at factory for easy installation. Electrical & Power Requirements: All electrical components are UL Approved / NEC compliant. Standard 115V, 15A 1 Ph, 60 Hz., 15 ft. SJO power cord with 3-prong ground plug. 230V also available. Motor/Blower Assembly: High efficiency Impellor motors reduce electrical load. Motors are thermally protected & self-lubricating. High capacity metal backward curved impellers within direct drive external rotor motors to reduce wear. Statically balanced to maintain constant airflow. Electrical & Power Requirements: All electrical components are UL Approved / NEC compliant. Standard 115V, 15A 1 Ph, 60 Hz., 15 ft. SJO power cord with 3-prong ground plug. 230V also available. Motor/Blower Assembly: High efficiency Impellor motors reduce electrical load. Motors are thermally protected & self-lubricating. High capacity metal backward curved impellers within direct drive external rotor motors to reduce wear. Statically balanced to maintain constant airflow. Lighting: Recessed 2 pin fluorescent “cleanroom” type sealed 4 bulb lights – 125 ft. candle +/-20 ft. candles. Plastic prismatic lens cover maximizes light diffusion. Controls: Solid state airflow control, 70-120 fpm. 15A load capacity. Individual switches for motor & lights. Drawings: A complete set will be provided for all Cleanroom projects with an easy installation guide included OR take advantage of LM Air’s – Six Step Cleanroom Solution – design assistance, project management, installation (LM Air’s trained staff) and maintenance. Options:

|

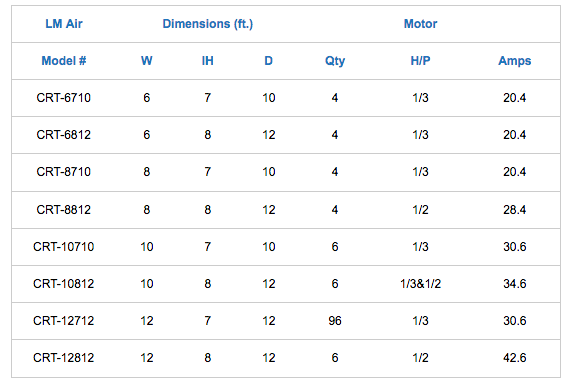

Model & Dimensions:

Horizontal Laminar Airflow Cleanroom Tunnel with WM Series Horizontal Laminar Airflow Modules:

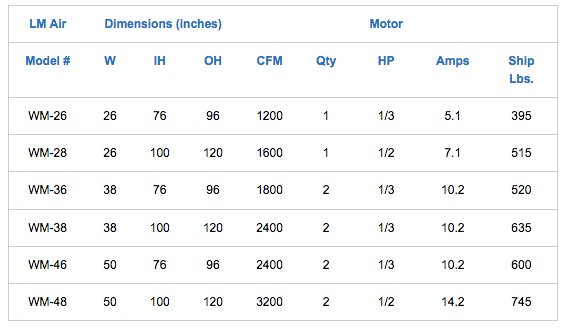

WM Series Horizontal Laminar Airflow Modules:

Sample Drawing:

Services |