Cleanroom, Hardwall & Softwall

Cleanroom Classification & Design Guidelines

|

Description:

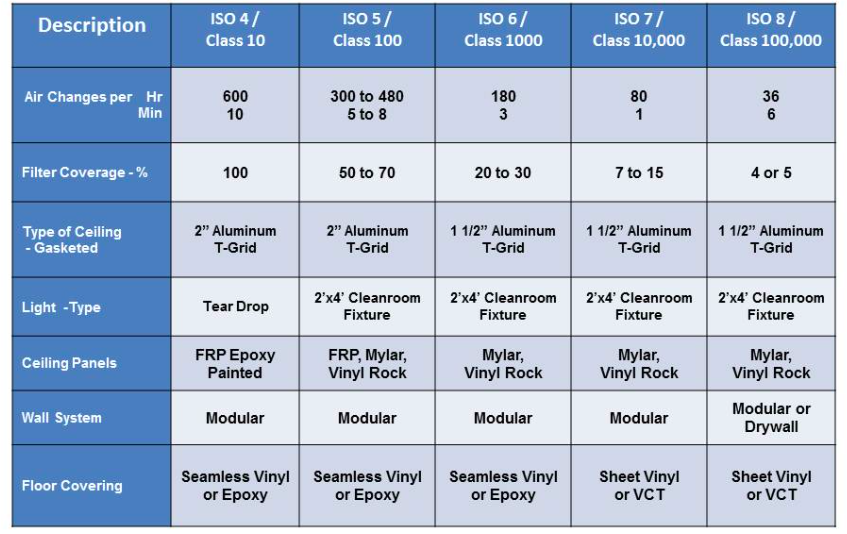

Cleanrooms are rated for purity according to guidelines established in Federal Standard 209D and ISO standard 14644. Air cleanliness is specified in terms of the number of foreign particles per cubic foot (or cubic liter) of air, relating different combinations of particle size and particle count. Lower classifications represent cleaner rooms (E.g.: Class 100 / ISO 5 is cleaner than Class 100,000 / ISO 8). How particles are counted depends on particle size: air with smaller particles can have higher particle counts and still meet the class designation.

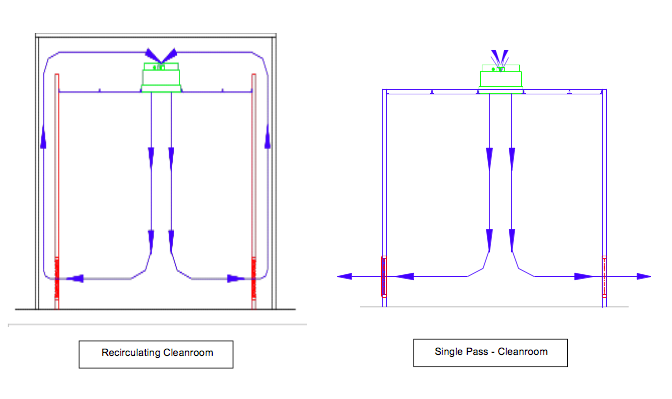

There are (2) distinct types of Hardwall Cleanrooms:

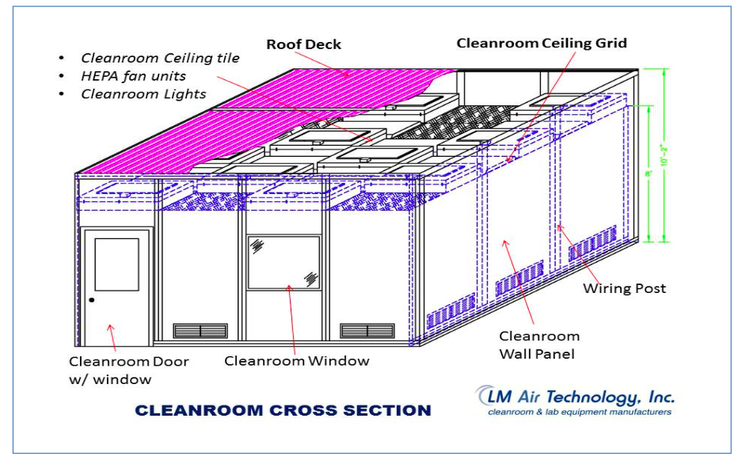

Hardwall Cleanrooms are designed to provide a Clean, Controlled Environment. Cleanroom levels are available from Class 100,000 to Class 1 (ISO Standards Class 1 thru Class 8), Temperature and/or Humidity control may need to be considered. The standard system consists of Panelized Cleanroom Walls, available in various thickness and textures. The system includes “H” post – wiring posts every 4’ on center; the structural members that support the Roof and Ceiling system. Filtered air is provided by Self Powered Filter Units (HEPA filtered diffusers) mounted in Ceiling. These take outside air through Prefilters, delivering filtered air through a HEPA (or ULPA) filter into Cleanroom. Filtered air is exhausted from Cleanroom thru Exhaust Vents near Floor level. Clean levels vary depending on quantity and configuration of Filters. All components are prefabricated and completely Modular in design; modular rooms are considered Equipment, which may be a tax benefit. Softwall Cleanrooms are designed to provide clean environments from Class 100,000 to Class 10 (ISO Standards Class 3 thru Class 8). This system consists of a Tubular Steel Frame Structure that supports the Ceiling Grid and Clear Vinyl Curtain Wall material. Filtered air is provided by Self Powered Filter Units mounted in-Ceiling that draw outside air thru a Prefilters and deliver filtered air through a HEPA filter into Cleanroom. Filtered air is exhausted from Cleanroom beneath the Curtain at Floor level. Clean levels will vary depending on quantity and configuration of Filters. All components are pre-assembled and completely modular in design. Softwall Cleanrooms can be installed by End User or by our professional trained installers. |

Re-circulating & Single-Pass Cleanrooms:

Services |